OPUS

Description

Versions

Downloads

Description

UV spectral sensor for online measurement of nitrogen and carbon with a resolution of 0.8 nm/pixel.

OPUS is the new generation of spectral probes for the online measurement of nitrogen and carbon compounds. By analyzing a complete spectrum, OPUS is able to provide reliable readings for N-NO3, N-NO2, organic compounds (CODeq, BODeq, DOCeq, TOCeq) and a range of other parameters.

OPUS is equipped with the new TriOS G2 interface, which enables simple and fast sensor configuration using a web browser. Integration into existing process control systems and external data loggers has never been easier.

Using WLAN, a laptop, tablet or smartphone can then simply be used for control without the need to install special application software or an app.

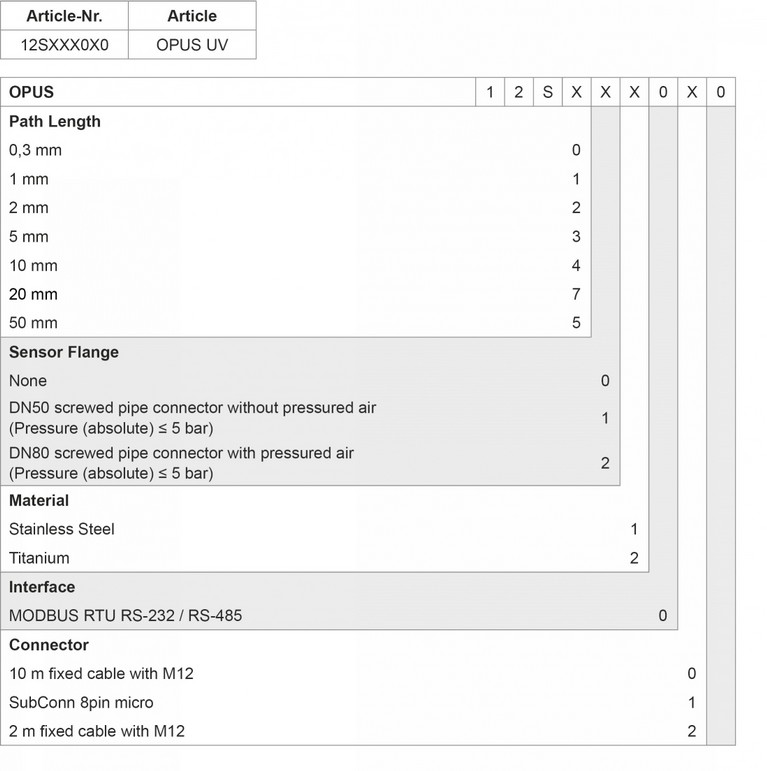

Versions

Downloads

OPUS

Benefits

- Without sampling and preparation of test samples

- Real-time sensor

- Without reagents

- Optical window with nano coating

- Pre-installed application calibration

Areas of application

- Sewage treatment plants

- Environmental monitoring

- Drinking water monitoring

- Industrial applications

Parameters

- NO3 / NO3-N

- NO2 / NO2-N

- CODeq

- BODeq

- DOCeq

- TOCeq

- TSSeq

- KHP

- SAC254

- COD-SACeq

- BOD-SAKeq

- SACeq